Graphene Heating Technology

Graphene heating management products - graphene heating film

- Realized the development and mass production of graphene large-area heating film;

-

Using the graphene conductive ink formulation independently developed by PMA Group, the ultra-flexible graphene polymer composite conductive film is prepared through standardized process steps, and combined with PI-based flexible circuit board (FPC) technology for packaging to achieve high performance and high reliability;

- It has the characteristics of fast heating rate, high heating uniformity, high electrothermal radiation conversion efficiency, softness and high reliability.

Graphene heating management system - Bifang AI system

Based on strong R&D and user data accumulation, the Bifang AI intelligent temperature control system independently developed by PMA Group can dynamically control the temperature according to the use environment and automatically correct the temperature difference.

Technology R&D Laboratory

PMA Group has the only comprehensive laboratory of graphene heating film in East China, which is also the only comprehensive experiment in East China with full-process R&D capability and small batch production capacity of PI-based graphene flexible heating film and third-generation cloth-based heating film.

The experimental center can undertake the research and development, proofing and testing of graphene flexible heating films of various sizes and shapes, as well as comprehensive evaluation and exploration of graphene heating films in smart wearable apparel products, healthcare products, textile products, medical protective gear applications, smart outdoor products and other fields.

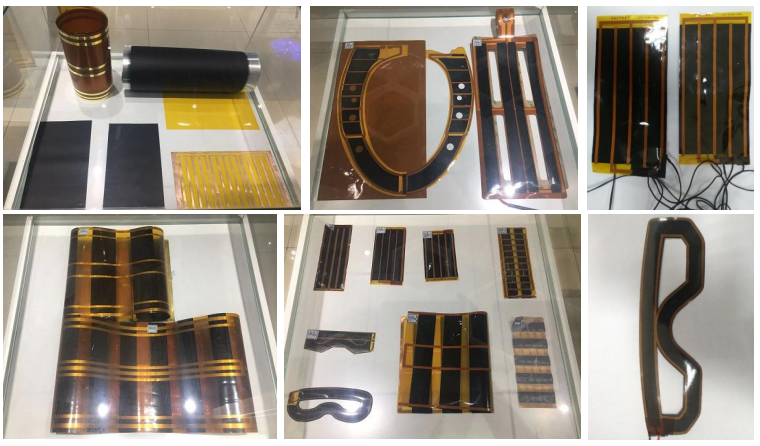

Graphene Heating Films Have Been Designed and Developed

PMA Group has designed and developed a variety of graphene heating films for use in various products.

Graphene Heating Application Products

PMA Group has developed a number of graphene heating application products, such as heated waist belts and heated neck pad in graphene healthcare applications; heated vests and heated jackets in graphene apparel applications; heated blankets and heated pillow blankets in graphene homeware applications; heated sleeping bag and heated gloves in graphene outdoor applications.

PMA Group also uses graphene far-infrared heating and independent R&D of heating management systems to develop medical devices and equipment used in the medical field, which will become an important force in solving the traditional medical dilemma.

Application of graphene heating film in the field of medical equipment

Combining the self-made graphene electric heating film heating with the heating management application data model developed by us, the problem of insufficient vaporization capacity caused by the freezing of the hospital liquid oxygen vaporizer during operation is solved, the normal vaporization is ensured, and the liquid oxygen vaporizer is effectively avoided due to manual deicing damage and increase the service life.

Application of graphene heating film in new energy vehicles

Lithium batteries used in new energy vehicles cannot work directly at low temperatures, and the battery needs to be heated to more than 5 degrees, otherwise the service life and performance of the battery will be greatly affected.

At present, the heating equipment of lithium battery in the world is mainly water circulation heating, ceramic heating and metal plate heating. PMA Group has pioneered the development of graphene heating modules. The current generation of products has obvious advantages such as stable energy efficiency, light weight and low price.

New Generation of Graphene Heating Film

The PMA Group is the first and only one in the world; it is composed of graphene conductive film, FPC circuit board and waterproof cloth packaging material.

Core Technology:

1. Solve the waterproof problem of packaging cloth;

2. Developed high-reliability FPC circuit board to solve the problem of washing resistance;

3. Developed an ultra-thin, ultra-flexible graphene conductive film.

Technical advantages:

1. Break through the large size heating limit;

2. Solved the problem of abnormal sound when kneading and bending.