Structure of graphite and its intercalation compounds

In 1859 Benjamin Brodie noted the highly lamellar structure of thermally reduced graphite oxide.

In

1916, Peter Debije and P. Scherrer determined the structure of graphite

by powder X-ray diffraction. The structure was studied in more detail

by V. Kohlschütter and P. Haenni in 1918, who also described the

properties of graphite oxide paper. Its structure was determined from

single-crystal diffraction in 1924.

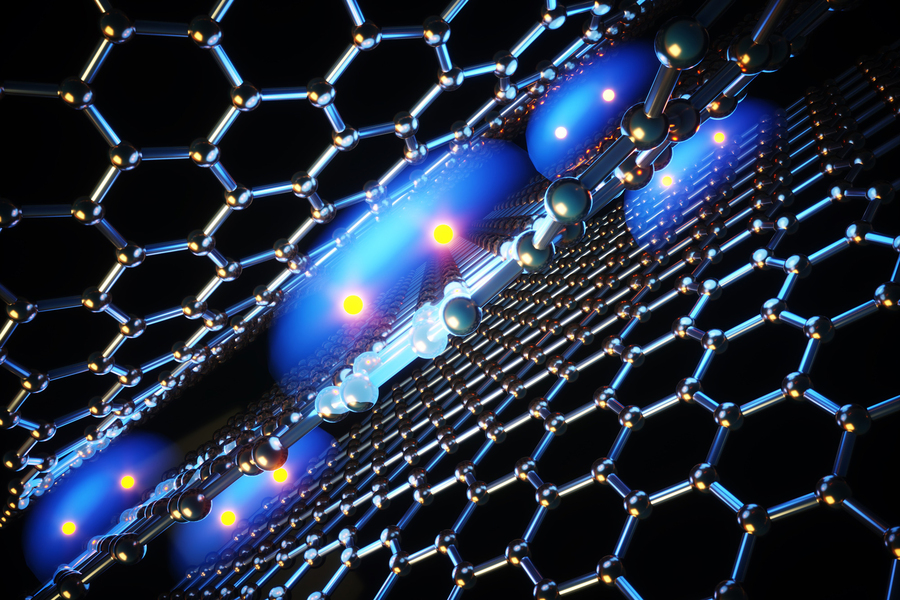

The

theory of graphene was first explored by P. R. Wallace in 1947 as a

starting point for understanding the electronic properties of 3D

graphite. The emergent massless Dirac equation was first pointed out in

1984 separately by Gordon Walter Semenoff, and by David P. DiVincenzo

and Eugene J. Mele. Semenoff emphasized the occurrence in a magnetic

field of an electronic Landau level precisely at the Dirac point. This

level is responsible for the anomalous integer quantum Hall effect.

Observations of thin graphite layers and related structures

Transmission

electron microscopy (TEM) images of thin graphite samples consisting of

a few graphene layers were published by G. Ruess and F. Vogt in 1948.

Eventually, single layers were also observed directly. Single layers of

graphite were also observed by transmission electron microscopy within

bulk materials, in particular inside soot obtained by chemical

exfoliation.

In

1961–1962, Hanns-Peter Boehm published a study of extremely thin flakes

of graphite, and coined the term "graphene" for the hypothetical

single-layer structure. This paper reports graphitic flakes that give an

additional contrast equivalent of down to ~0.4 nm or 3 atomic layers of

amorphous carbon. This was the best possible resolution for 1960 TEMs.

However, neither then nor today is it possible to argue how many layers

were in those flakes. Now we know that the TEM contrast of graphene most

strongly depends on focusing conditions. For example, it is impossible

to distinguish between suspended monolayer and multilayer graphene by

their TEM contrasts, and the only known way is to analyze the relative

intensities of various diffraction spots. The first reliable TEM

observations of monolayers are probably given in refs. 24 and 26 of Geim

and Novoselov's 2007 review.

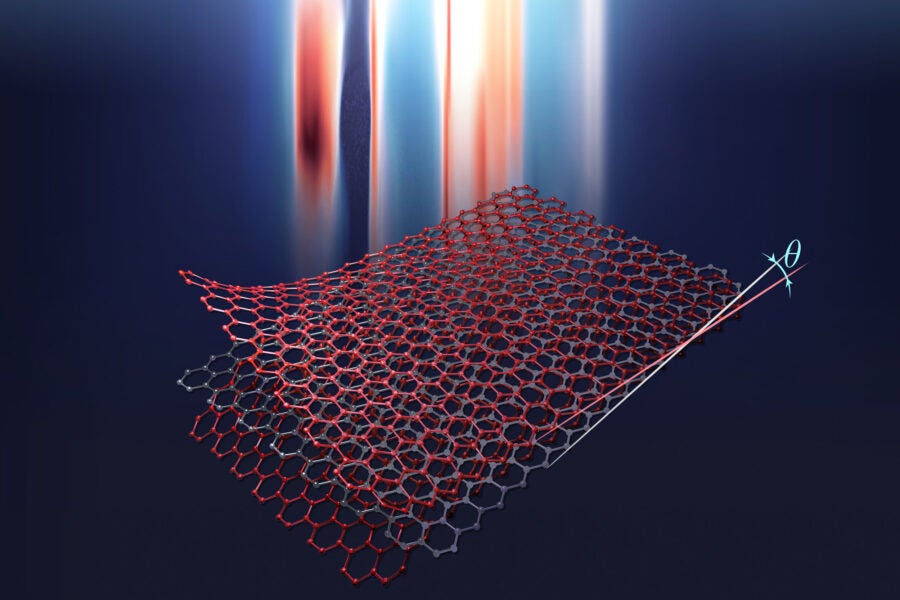

Starting

in the 1970s, C. Oshima and others described single layers of carbon

atoms that were grown epitaxially on top of other materials. This

"epitaxial graphene" consists of a single-atom-thick hexagonal lattice

of sp2-bonded carbon atoms, as in free-standing graphene. However, there

is significant charge transfer between the two materials, and, in some

cases, hybridization between the d-orbitals of the substrate atoms and π

orbitals of graphene; which significantly alter the electronic

structure compared to that of free-standing graphene.

The

term "graphene" was used again in 1987 to describe single sheets of

graphite as a constituent of graphite intercalation compounds, which can

be seen as crystalline salts of the intercalant and graphene. It was

also used in the descriptions of carbon nanotubes by R. Saito and

Mildred and Gene Dresselhaus in 1992, and of polycyclic aromatic

hydrocarbons in 2000 by S. Wang and others.

Efforts

to make thin films of graphite by mechanical exfoliation started in

1990. Initial attempts employed exfoliation techniques similar to the

drawing method. Multilayer samples down to 10 nm in thickness were

obtained.

In

2002, Robert B. Rutherford and Richard L. Dudman filed for a patent in

the US on a method to produce graphene by repeatedly peeling off layers

from a graphite flake adhered to a substrate, achieving a graphite

thickness of 0.00001 inches (2.5×10−7 metres). The key to success was

high-throughput visual recognition of graphene on a properly chosen

substrate, which provides a small but noticeable optical contrast.

Another U.S. patent was filed in the same year by Bor Z. Jang and Wen C. Huang for a method to produce graphene based on exfoliation by attrition.

Full isolation and characterization

Graphene

was properly isolated and characterized in 2004 by Andre Geim and

Konstantin Novoselov at the University of Manchester. They pulled

graphene layers from graphite with a common adhesive tape in a process

called either micromechanical cleavage or the Scotch tape technique. The

graphene flakes were then transferred onto thin silicon dioxide

(silica) layer on a silicon plate ("wafer"). The silica electrically

isolated the graphene and weakly interacted with it, providing nearly

charge-neutral graphene layers. The silicon beneath the SiO2 could be

used as a "back gate" electrode to vary the charge density in the

graphene over a wide range.

This

work resulted in the two winning the Nobel Prize in Physics in 2010

"for groundbreaking experiments regarding the two-dimensional material

graphene." Their publication, and the surprisingly easy preparation

method that they described, sparked a "graphene gold rush". Research

expanded and split off into many different subfields, exploring

different exceptional properties of the material—quantum mechanical,

electrical, chemical, mechanical, optical, magnetic, etc.

Exploring commercial applications

Since the early 2000s, a number of companies and research laboratories have been working to develop commercial applications of graphene. In 2014 a National Graphene Institute was established with that purpose at the University of Manchester, with a 60 million GBP initial funding. In North East England two commercial manufacturers, Applied Graphene Materials and Thomas Swan Limited have begun manufacturing. Cambridge Nanosystems is a large-scale graphene powder production facility in East Anglia. Till now, PMA Group produce all kinds of Graphene heating product, such as Graphene heated waist and hand massagers.