Recently, Dezhou Aerospace & PMA Graphene Tech. Co., Ltd. (hereinafter referred to as "Dezhou PMA") has broken through the large-scale graphene high-precision heating film technology and achieved mass production.

Prior to this, this kind of large-scale heating film was unique. Generally, the "large-area" heating demand was realized by connecting small pieces in series. There are also many so-called large-area heating film heating elements that are not actually graphene. Graphene is actually used as a The heating element is prepared with a large-area heating film, and Dezhou PMA has achieved a technological breakthrough in this industry.

This project was led by Dr. Zhou Ming, CTO of PMA Group, and the heating technology team of PMA Group participated in the whole process. The graphene heating whole process laboratory of PMA Group and the Phoenix heating workshop of Dezhou PMA worked together for half a year. Finally, the development and mass production of graphene large-area heating film was realized. This technology mainly makes breakthroughs in various details such as slurry configuration, conductive sheet improvement, original flexible packaging process, and non-inductive wiring.

In terms of slurry configuration, in order to achieve the same heating efficiency and large-area heating requirements, we have reduced the unit square resistance; the conductive sheet and the heating film are produced by traditional etching, which not only costs high, but also brings For environmental pollution and waste of materials, Aerospace Paramount has improved its technology and adopted original technology to meet the needs of electricity conduction; more original flexible packaging technology can ensure stable heating efficiency and meet the requirements of waterproof and bending resistance .

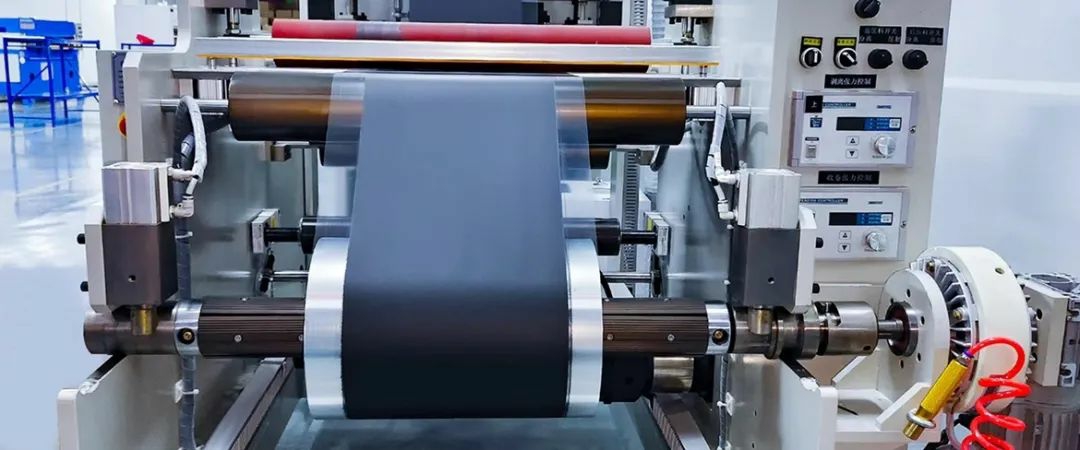

Dezhou PMA is a wholly-owned subsidiary headquartered in Dezhou. It is an enterprise specializing in the research, development and production of graphene electrothermal film. Its production base covers an area of 40,000 square meters. It has a graphene heating film and heat dissipation film production line with complete intellectual property rights, an intelligent assembly line, and a fully automatic product plastic packaging line. It uses a self-developed graphene conductive ink formula and standardized process steps. Prepare ultra-flexible graphene polymer composite conductive film, and combine PI-based flexible circuit board (FPC) technology for packaging to achieve high-performance and high-reliability heating film preparation. At present, the annual production capacity of graphene electric heating film has reached 1,500,000 square meters, which is at the leading level in the domestic industry.

The technological breakthrough of the large-size graphene high-precision heating film is an important milestone in the development history of Aerospace Paramount. It not only broadens the new field of graphene heating application of Aerospace Paramount, but also adds new opportunities to our entire industry. Vitality, inject new vitality.